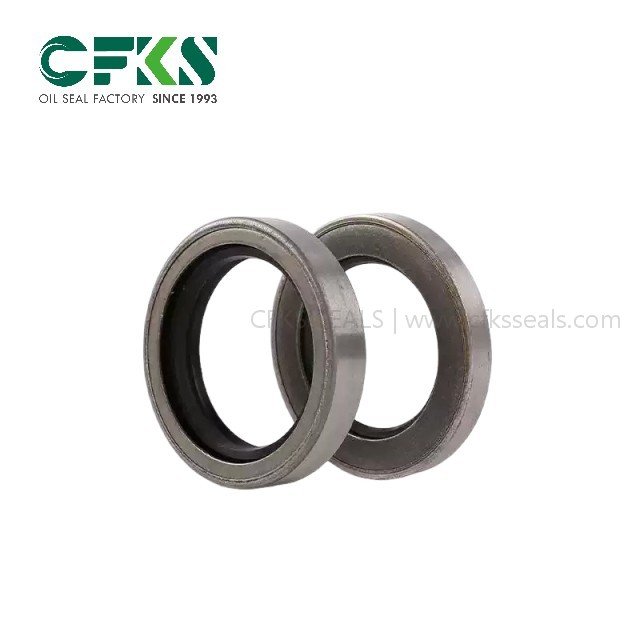

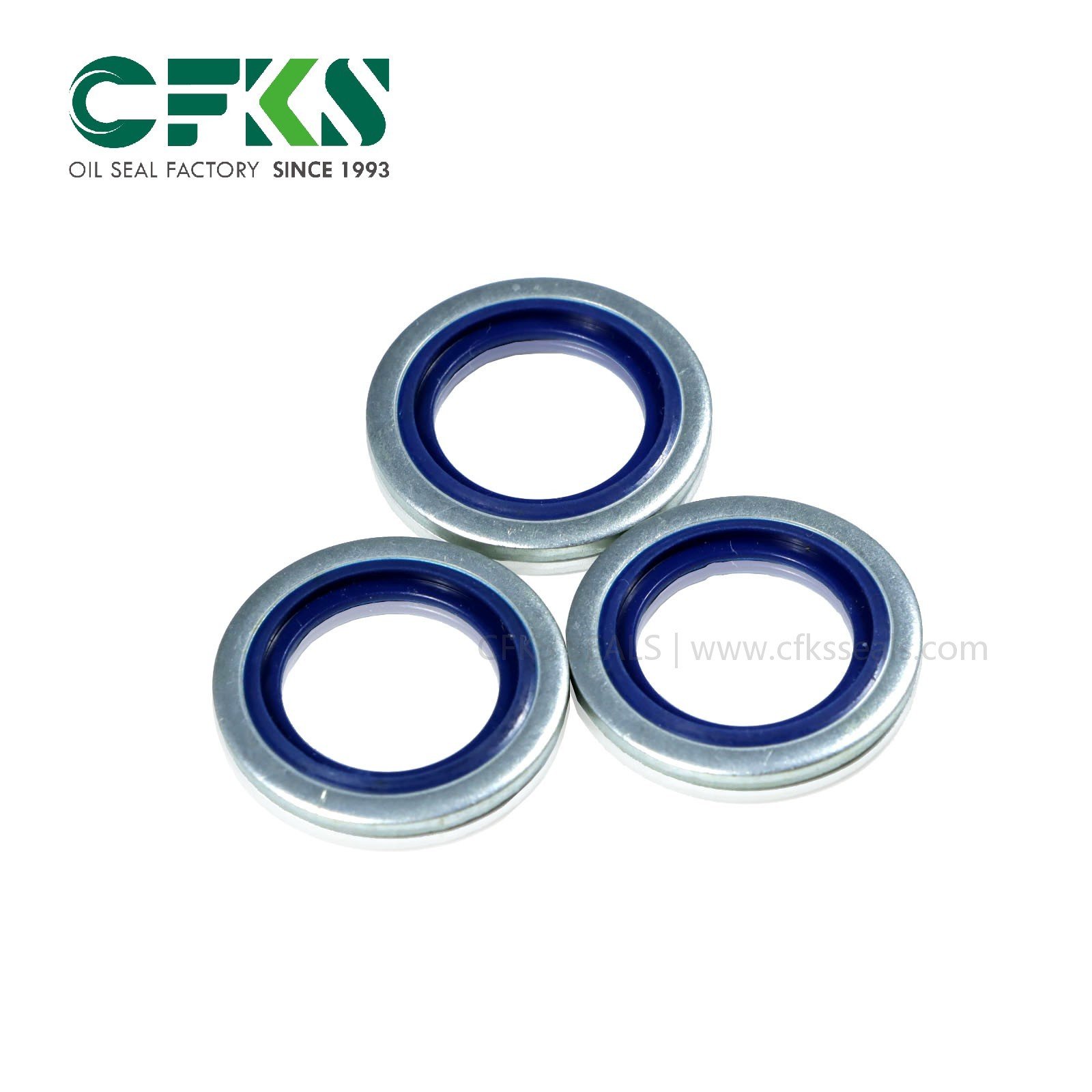

CFKS TA Type Oil Seal 35*52*10 Mechanical Oil Seal

The CFKS 35*52*10 TA Oil Seal is a premium double metal case mechanical oil seal engineered for high-precision industrial environments. Featuring a reinforced double-lip structure, this TA Oil Seal provides exceptional dust protection and lubricant retention for gearboxes and motors. Find your sealing solution with CFKS — contact us for a quote.

Product Categories

Recent Posts

- CFKS Expert Hydraulic Seals: Precision Sealing Solutions for Demanding Applications

- CFKS Deepens Industry Expertise with High-Performance Washing Machine Seals

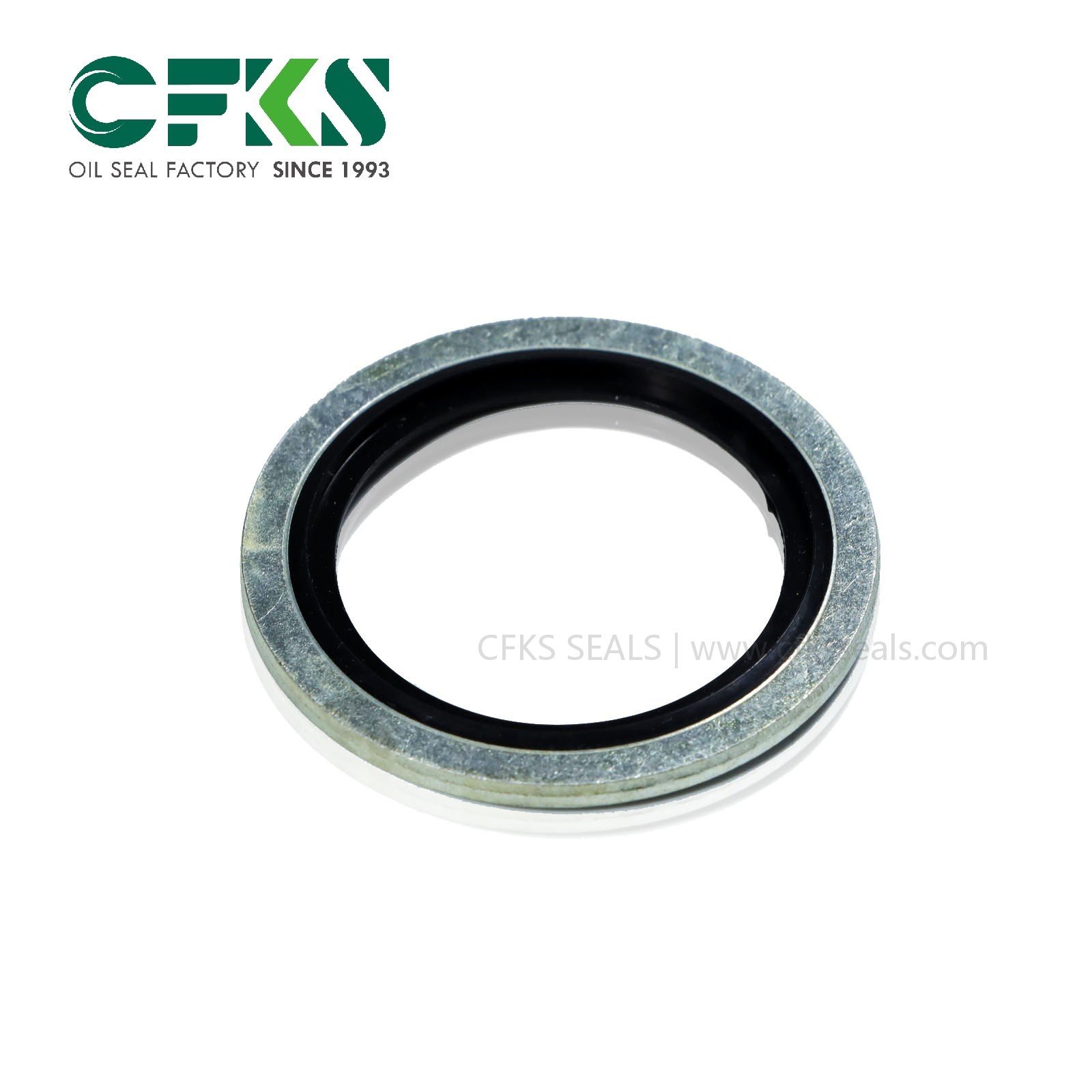

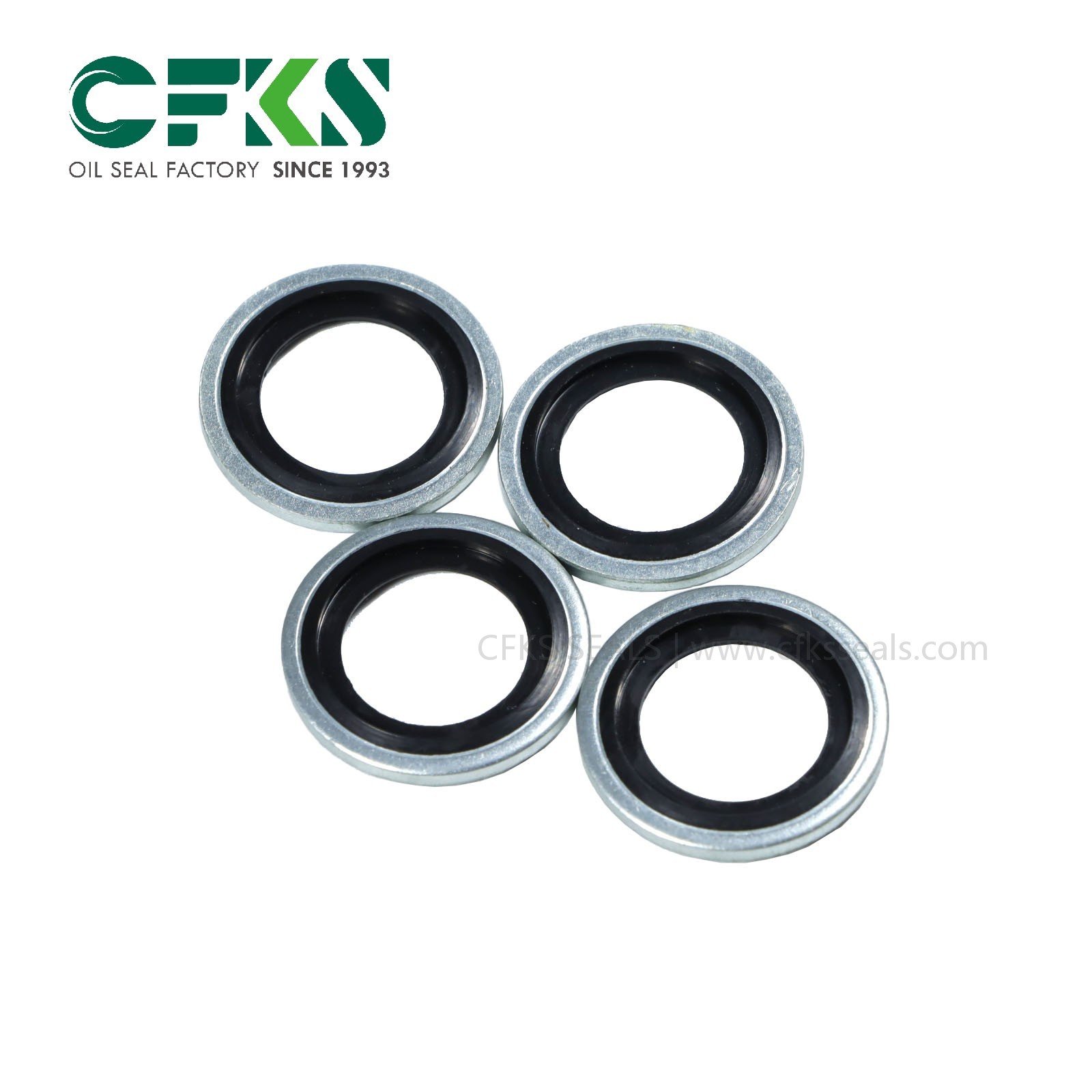

- Understanding Bonded Seals: Structure, Function, and Applications

- CFKS Expands Its Hydraulic Sealing Portfolio with High-Performance TG Oil Seals for Rotary Shaft Applications

- CFKS Launches High-Performance Combi Oil Seals for Demanding Industrial Applications

| Brand Name | CFKS | OEM | Accpetable |

|---|---|---|---|

| Material | NBR FKM Silicone | Features | wear resistance |

| Dimensions | Customized | Certificate | ISO9001/TS16949 |

| Type | TA Seal | Packing | 1 pc per bag |

The CFKS 35*52*10 TA Oil Seal is defined by its robust double metal case design, which offers significantly higher structural rigidity compared to standard single-case seals. This “reinforced” architecture is specifically developed for high-precision applications where the seal must maintain its shape under intense mechanical stress or high-vibration conditions. The metal-to-metal contact between the seal’s outer diameter and the housing ensures a secure, leak-free press-fit, effectively preventing the TA Oil Seal from shifting or distorting during high-speed rotation.

Engineered for longevity, this mechanical oil seal utilizes a sophisticated double-lip configuration. The primary sealing lip is reinforced with a high-tension garter spring to maintain constant radial pressure on the shaft, while the secondary auxiliary lip serves as a vital shield against external dust, moisture, and debris. This dual-protection system makes the TA Oil Seal exceptionally reliable for equipment operating in contaminated environments. Available in high-grade NBR or FKM, it provides excellent resistance to thermal degradation and aggressive industrial lubricants.

The 35*52*10 size is a standard specification for electric motors, small industrial gearboxes, and centrifugal pumps. By choosing a CFKS TA Oil Seal, maintenance professionals can achieve longer service intervals and reduced total cost of ownership. The heat-conductive properties of the double metal shell help dissipate frictional heat away from the sealing interface, protecting the shaft and preventing premature seal failure. Whether for OEM manufacturing or aftermarket repairs, our TA Oil Seals deliver the stability and precision required for modern industrial drive systems.

Frequently Asked Questions (FAQ)

Premature oil seal failure can result from improper installation, poor shaft finish, incorrect material selection, or excessive pressure. To prevent this, ensure the shaft surface is smooth and within tolerance, use correct tools during installation, and choose seals made from materials compatible with your media and temperature.

Always clean the shaft and bore before installation. Use appropriate seal drivers to avoid deformation. Lubricate the lip before fitting to reduce friction during the first rotation. Ensure the seal is seated evenly and not tilted to avoid leaks.

Check if the pressure exceeds the seal’s rated limit. Examine for wear, hardening, or improper installation. Replace the seal if damaged, and consider upgrading to a high-pressure CFKS seal variant. Also, verify that the housing and shaft are properly aligned.

For high temperatures, aggressive chemicals, or abrasive environments, choose CFKS seals made of FKM, PTFE, or high-performance elastomers. Consider using seals with protective dust lips or metal casing. Our team can recommend the best fit for your application.

| CFKS Seal Manufacturing Co.,Ltd. | ||

|---|---|---|

| https://cfksseals.com/ | ||

| Email:cfksnacy@gmail.com Mobile/WhatsApp/Wechat:(86)188-3097-5917 | ||

| TA Oil Seal Size List | ||

| SIZE | Material | Core Application |

| 35*52*10 | NBR | Centrifugal Pumps & Transmission Shafts |

| 40*62*12 | NBR | Hydraulic Pumps & Agricultural Machinery |

| 45*65*12 | NBR | Industrial Reducers & Conveyor Systems |

| 50*72*12 | NBR/FKM | Industrial Fan & Blower Assemblies |

| 55*80*12 | NBR | Tractor Drive Axles & Power Take-Offs |

| 60*85*12 | NBR | Water Treatment Pumps & Mixers |

| 65*90*12 | NBR | Marine Propulsion & Stern Drive Systems |

| 70*95*13 | NBR/FKM | Construction Machinery Wheel Hubs |

| 75*100*12 | NBR | Heavy-Duty Industrial Gearboxes |

| 80*105*13 | NBR/FKM | Truck Axle Repair & Drivetrains |

| 85*110*13 | NBR | Metal Rolling Mill Equipment |

| 90*115*13 | NBR | Excavator Final Drives & Travel Motors |

| 95*120*13 | NBR | Pulp & Paper Processing Machinery |

| 100*125*13 | NBR/FKM | Mining Conveyor Roller Assemblies |

| 105*135*14 | NBR | Chemical Processing Pumps & Agitators |

| 110*140*14 | NBR/FKM | Agricultural Harvester Transmissions |

| 115*145*14 | NBR | Heavy-Duty Earthmoving Equipment |

| 120*150*15 | NBR/FKM | Industrial Ventilation & Cooling Units |

| 125*155*15 | NBR | Steel Production Line Rollers |

| 130*160*15 | NBR/FKM | Cement & Concrete Mixing Plants |

| 135*165*15 | NBR | Ship Engine Crankshaft Seals |

| 140*170*15 | NBR/FKM | Large Bore Hydraulic Cylinders |

| 145*175*15 | NBR | Wind Turbine Main Shaft Bearings |

| 150*180*15 | NBR/FKM | Quarrying Machinery & Stone Crushers |

| 155*185*15 | NBR | Rubber & Plastic Extrusion Lines |

| 160*190*16 | NBR/FKM | Heavy Cargo Winches & Hoists |

| 165*195*16 | NBR | Large Gear Drives for Industrial Mills |

| 170*200*16 | NBR/FKM | Marine Dredging & Salvage Equipment |

| 175*210*16 | NBR | Petroleum Refining & Driller Machinery |

| 180*210*16 | NBR/FKM | Thermal Power Generation Turbines |

| 185*220*16 | NBR | Wastewater Aerator Drive Systems |

| 190*225*16 | NBR/FKM | Mining Shovel & Dragline Components |

| 195*230*16 | NBR | Heavy Steel Casting & Forging Machines |

| 200*240*18 | NBR/FKM | Sugar Mill Roller Drive Shafts |

| 210*250*18 | NBR/FKM | Tunnel Boring Machine (TBM) Cutters |

| 220*260*18 | NBR | Large Marine Propeller Shaft Seals |

| 230*270*18 | NBR/FKM | Port Handling & Container Cranes |

| 240*280*20 | NBR | Hydroelectric Power Station Valves |

| 250*290*20 | NBR/FKM | Large-Scale Industrial Air Compressors |

| 260*300*20 | NBR | Heavy Forging Presses & Hammers |

| 270*310*20 | NBR/FKM | Mining Excavator Chassis & Axles |