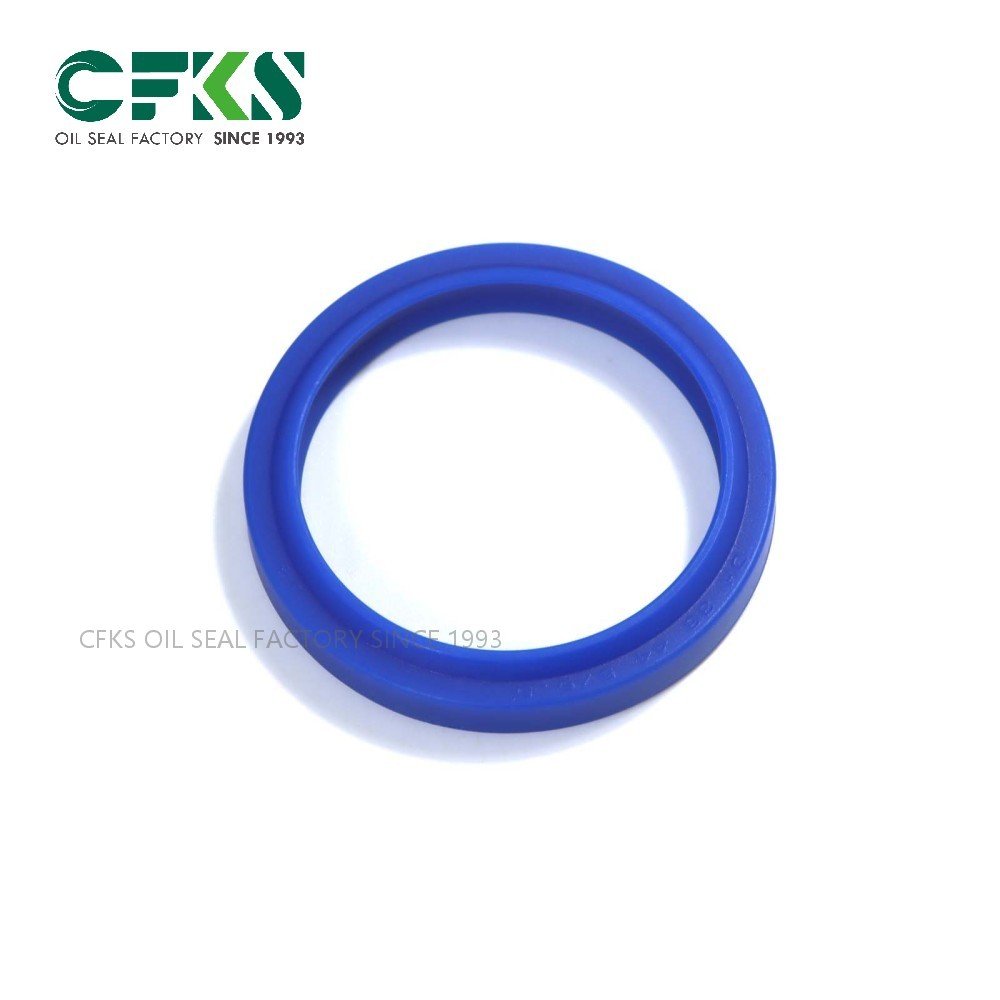

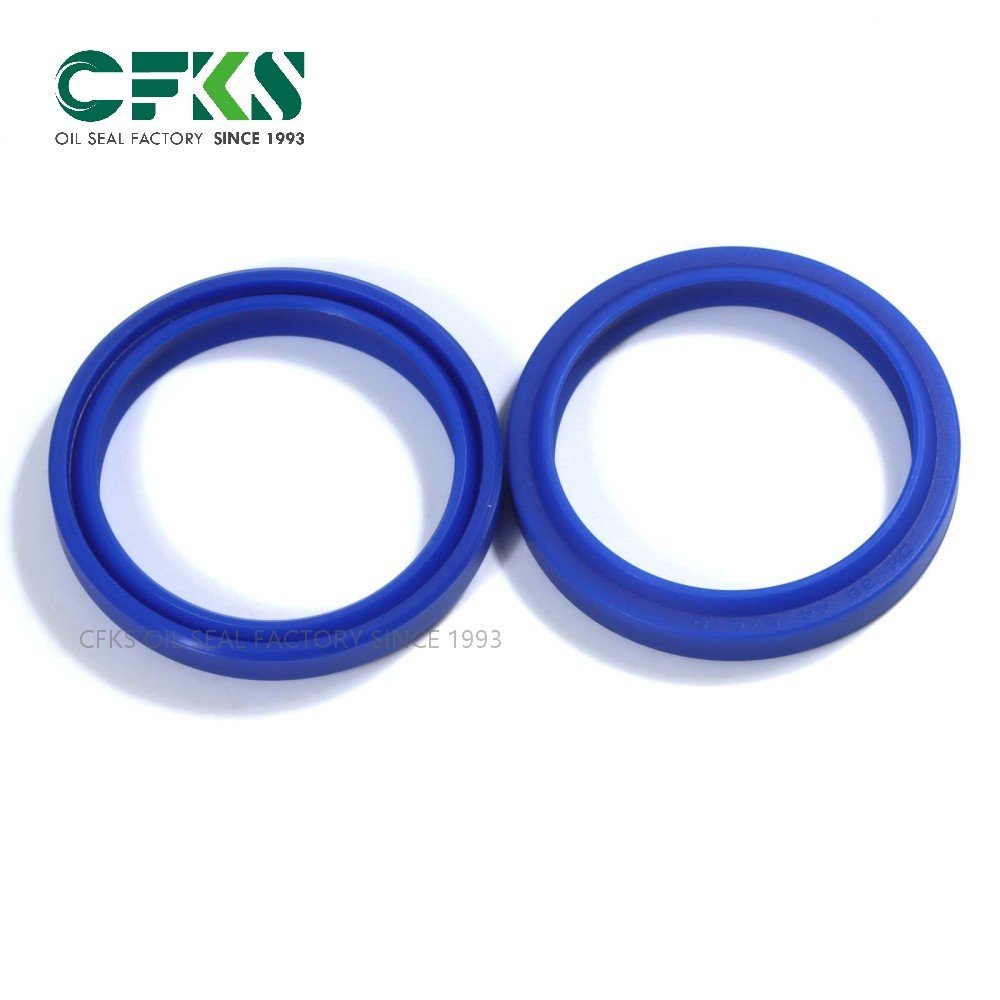

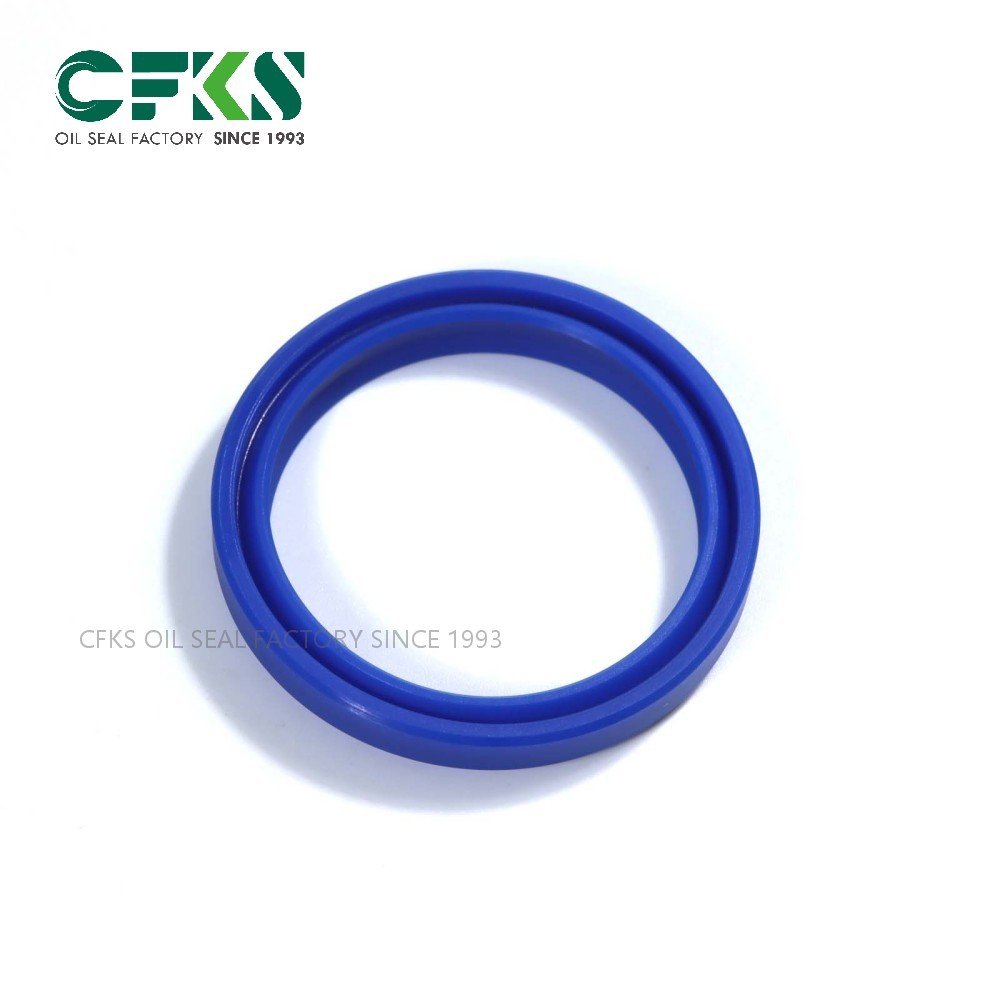

CFKS Piston Seals Cylinder Seal Dh Hydraulic Pneumatic Seal Rubber NBR FKM High-Performance Cylinder DH Seals

CFKS Guide Rings and Wear Rings are essential components for hydraulic cylinders, preventing metal-to-metal contact while guiding piston and rod movement. Available in fabric-resin composite and PTFE materials, they offer superior wear resistance and low friction for high-performance hydraulic systems.

Bonded Seal (12)

BS Seal (3)

Cassette Oil Seal (3)

Combi Oil Seal (3)

Construction Seal (9)

Coupling Spider (13)

DAS Seal (3)

DH Seal (4)

DHS Seal (3)

DK/DP Seal (3)

DLI Seal (3)

EC Cup Seal (3)

Glyd Ring (5)

Guide Ring (16)

HBY Seal (2)

High Pressure Water Seal (22)

Hydraulic Oil Seal (145)

IDU Seal (7)

JA Seal (5)

J Type Seal (5)

LBH Seal (2)

LBI Seal (2)

O-Ring/O-Ring Kit (12)

ODU Seal (8)

OK Seal (3)

OUY Seal (3)

Piston Seal (25)

Polyurethane Bump Stop (6)

Polyurethane Washer (3)

Power Transmission Parts (22)

Rod Seal (48)

Rotary Shaft Oil Seal (38)

Split Oil Seal (4)

Split Rotary Shaft Seal (3)

Spring Energized Seal (3)

Stainless Steel Oil Seal (3)

Step Seal (3)

TBV (20)

TC/TG Seal (100)

TCV/TCN (9)

UHS Seal (3)

UN/USH/UPH Rod Seal (21)

UPH Seal (2)

VA/VS Seal (3)

Wiper Seals/Dust Seal (36)