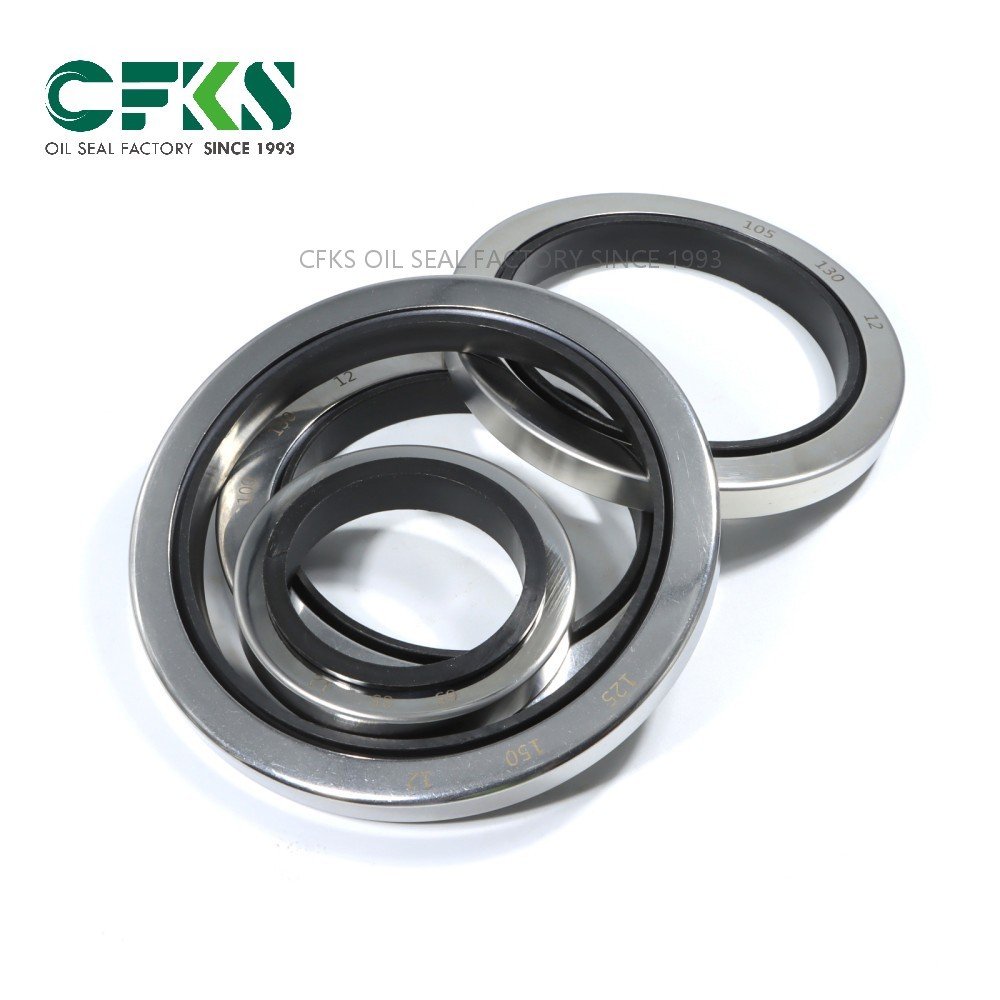

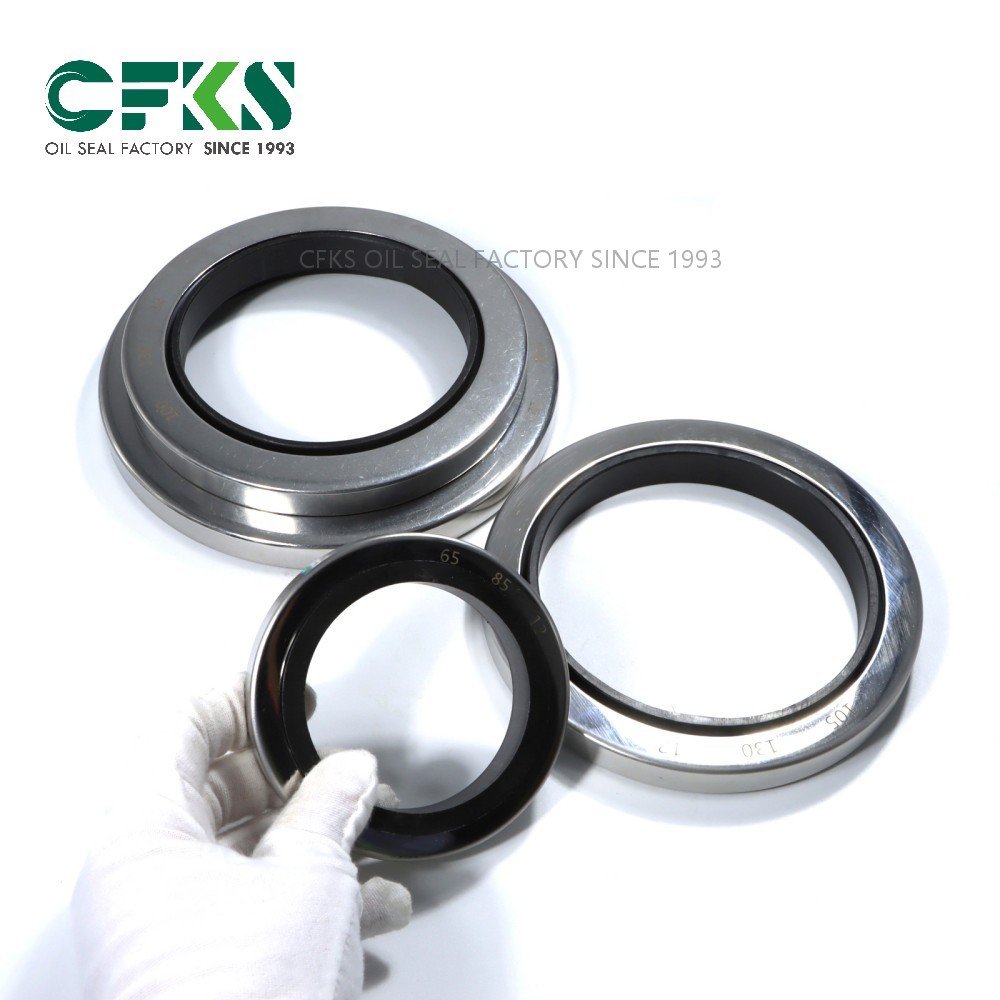

CFKS Stainless Steel PTFE Air Compressor Oil Seals Stainless Steel Oil Seal Industrial Shaft Seal for Pumps Engine Mixers Actuators

CFKS Stainless Steel PTFE Air Compressor Oil Seals offer superior durability and sealing performance in demanding industrial environments. Designed for pumps, engines, mixers, and actuators, these oil seals provide an effective barrier against contaminants, ensuring smooth operation and longevity of your machinery. Made with high-quality stainless steel and PTFE materials, these seals are ideal for high-pressure and high-temperature applications.

Bonded Seal (2)

BS Seal (2)

Cassette Oil Seal (2)

Combi Oil Seal (2)

Construction Seal (10)

Coupling Spider (2)

DAS/ODI Piston Seal (2)

DH Seal (2)

DKBI Seal (1)

DK Seal (2)

DLI Seal (1)

DWI Seal (1)

EC Cup Seal (3)

GA Seal (1)

Glyd Ring (2)

Guide Ring (4)

High Pressure Water Seal (2)

Hydraulic Oil Seal (24)

Mechanical Seal (2)

O-Ring/O-Ring Kit (2)

OK Seal (1)

OUY Seal (1)

Piston Seal (7)

Power Transmission Parts (2)

Rod Seal (4)

Rotary Shaft Oil Seal (8)

Split Oil Seal (2)

Spring Energized Seal (2)

Stainless Steel Oil Seal (2)

TC/TG Seal (95)

TCV/TCN (4)

UN/USH/UPH Rod Seal (4)

VA/VS Seal (2)

Wiper Seals/Dust Seal (9)

X-Ring (2)