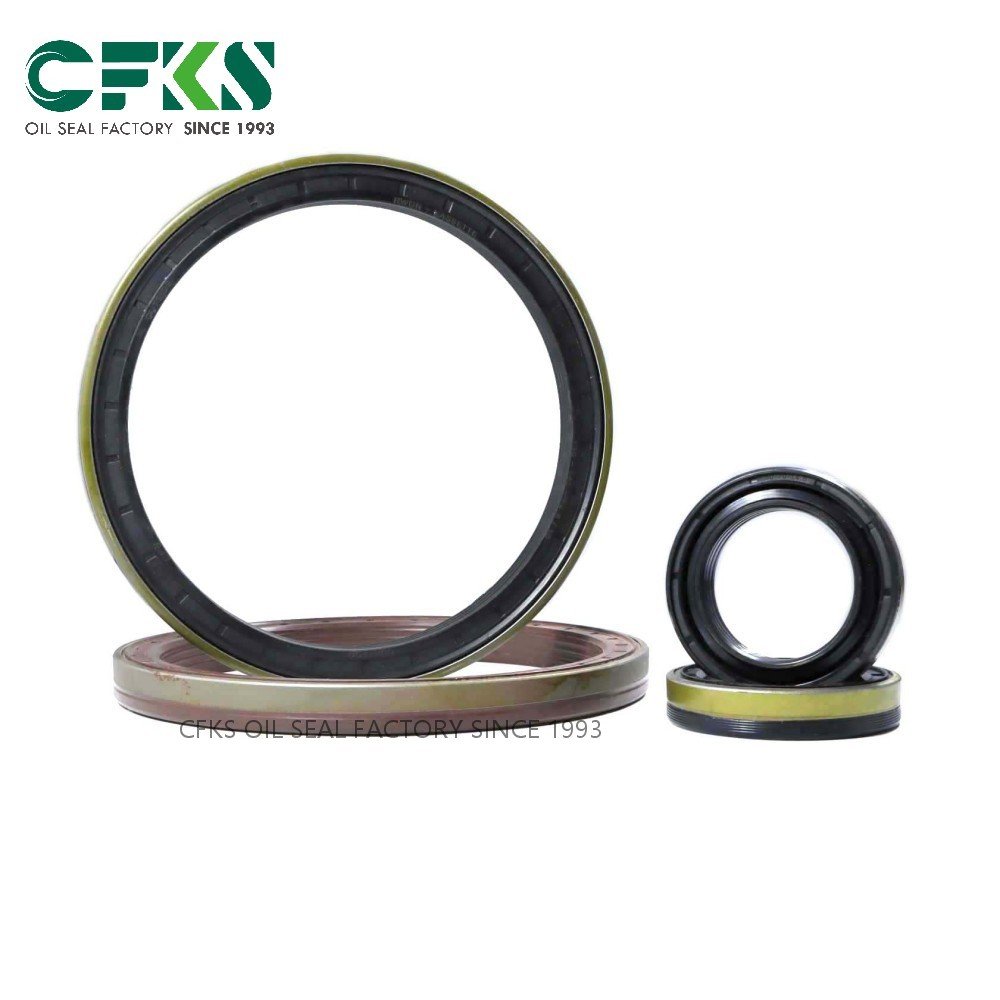

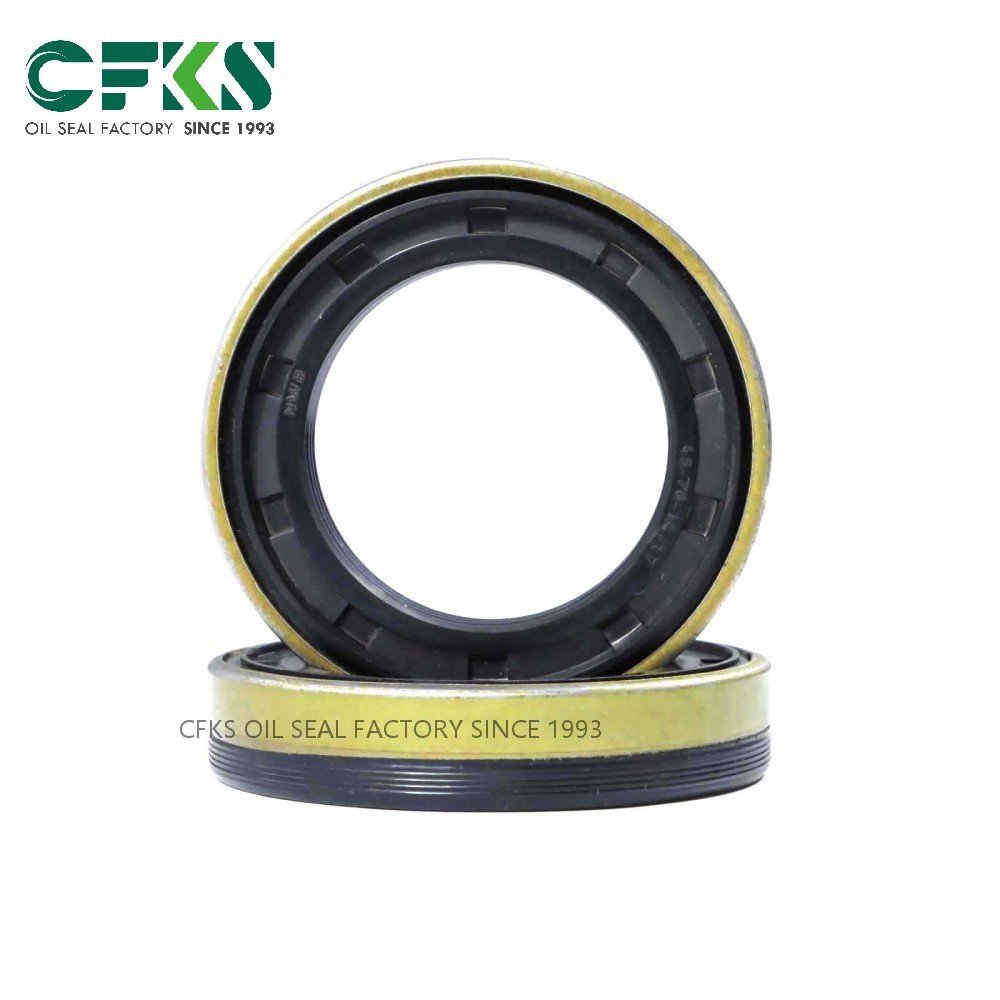

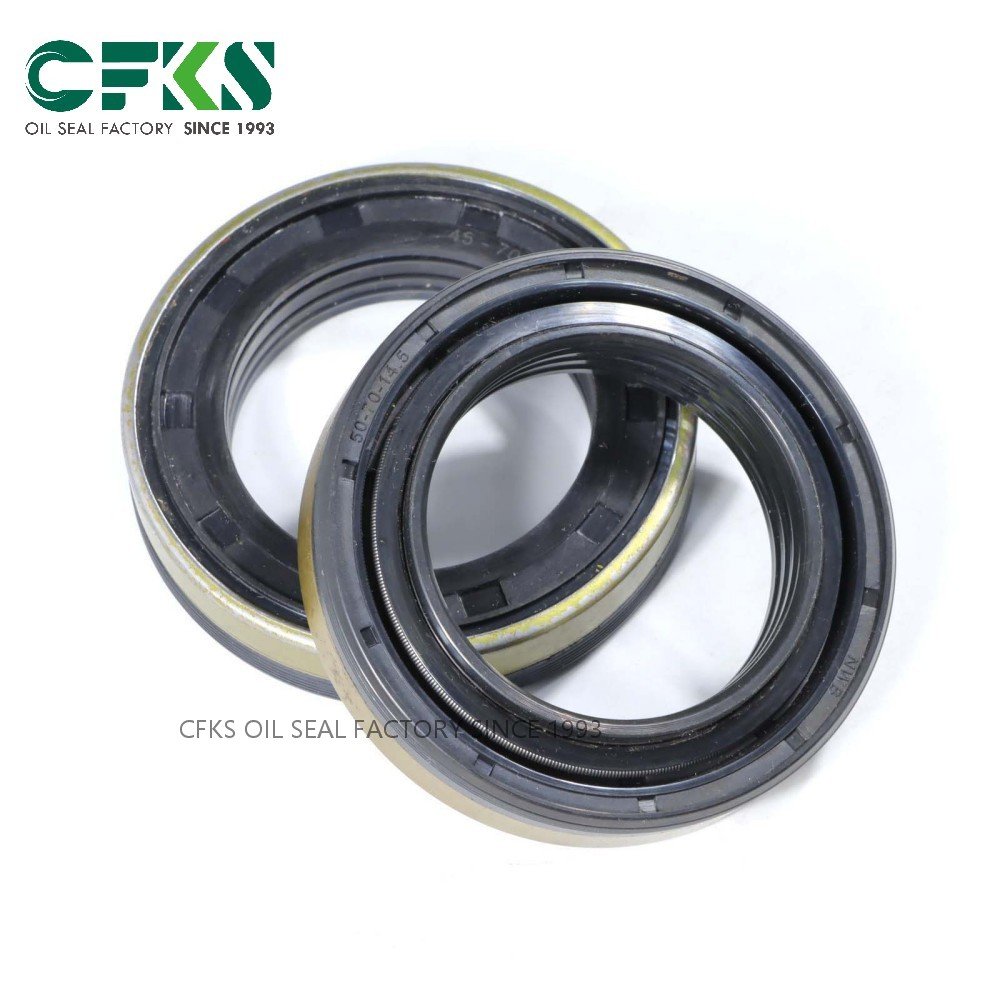

CFKS Cassette Oil Seal Tractor Wheel Hub Seal Cassette Wheel Hub Oil Seals

CFKS Cassette Oil Seal for tractor and machinery wheel hubs features a multi-lip design for superior dirt and moisture protection, offering high durability in extreme conditions. Compatible with NBR/FKM rubber and OEM specs for easy installation.

Bonded Seal (12)

BS Seal (3)

Cassette Oil Seal (3)

Combi Oil Seal (3)

Construction Seal (9)

Coupling Spider (13)

DAS Seal (3)

DH Seal (4)

DHS Seal (3)

DK/DP Seal (3)

DLI Seal (3)

EC Cup Seal (3)

Glyd Ring (5)

Guide Ring (14)

HBY Seal (2)

High Pressure Water Seal (22)

Hydraulic Oil Seal (143)

IDU Seal (7)

JA Seal (5)

J Type Seal (5)

LBH Seal (2)

LBI Seal (2)

O-Ring/O-Ring Kit (12)

ODU Seal (8)

OK Seal (3)

OUY Seal (3)

Piston Seal (25)

Polyurethane Bump Stop (6)

Polyurethane Washer (3)

Power Transmission Parts (22)

Rod Seal (48)

Rotary Shaft Oil Seal (38)

Split Oil Seal (4)

Split Rotary Shaft Seal (3)

Spring Energized Seal (3)

Stainless Steel Oil Seal (3)

Step Seal (3)

TBV (20)

TC/TG Seal (100)

TCV/TCN (9)

UHS Seal (3)

UN/USH/UPH Rod Seal (21)

UPH Seal (2)

VA/VS Seal (3)

Wiper Seals/Dust Seal (36)